- The Best Arabic Food, Manakish Oven & Grill Catering Service in Milpitas, CA

- Becoming the Trusted LNC: Building Strong Relationships with Attorneys

- The Crucial Role of Nutrition in Battling Oral Cancer and Legal Recourse for Dental Negligence

- Exploring the Cost of Veneers in South America

- Unveiling the Art of Securing Funding: Yanni Hufnagel’s Pearls of Wisdom for Confident Capital Procurement

Three Methods to Coat a Substrate Evenly

February 2, 2015Written by: Denton Vacuum, LLC

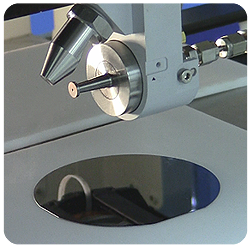

Certain devices that require precision, like the face plate of a medical device, can’t afford to be coated in layers of materials greater than a few microns in thickness. Doing so would make it impossible to put a device together after receiving a coating, because the pieces wouldn’t fit together. The solution involves precise control of temperature, and the ability to freely rotate an object in order to achieve that even coating. Here are three methods manufacturers have developed to accomplish exactly that.

Thermal

A thermal evaporation system has two distinct phases that the substrate goes through before the process is completed. First, the materials that will coat the object are superheated until they become gaseous particles. After the chamber is cooled, the substrate is placed within. The particulates of the materials bounce off the walls of the sealed chamber until they settle on the substrate. Throughout this process, the substrate is rotated at precise angles and intervals to evenly coat the surface.

Sputtering

A sputter deposition system works a bit differently from its thermal counterpart. You can picture sputtering a bit like the nozzle on a can of spray paint. The materials are forced out of a small opening to coat the substrate, which is rotated evenly to prevent material build up. Sputtering does have the chance of material build up in some situations, so it is often used in the anodizing of metals.

Optical Coatings

Optical coating systems are a form of precision coating that is often used in the field of astronomy. Tiny mirrors with highly reflective surfaces are placed within telescopes, allowing astronomers to see deep into space. These mirrors have a metallic coating (often containing titanium) which helps to reduce the absorption of light and improve optics.

Bio: Denton Vacuum, LLC specializes in advanced manufacturing devices like optical coating systems.